The Future Is Here

Published 8:00 am Friday, March 14, 2014

- The Future Is Here

By Rachel Gulotta / Photos submitted by Future Factory and Idea Zoo

3D Printing’s History

Charles W. Hull defined the term stereolithography as a “system for generating three-dimensional objects by creating a cross-sectional pattern of the object to be formed.” Today, Hull’s 1984 term is more aptly called additive manufacturing or 3D printing. The phrase “additive manufacturing” refers to the process in which three-dimensional solid objects are created from a digital model by laying down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the digital model, are joined or automatically fused to create the final shape. In a sense, 3D printers are like highly accurate glue guns with the ability to create almost any object you can imagine.

Home-printers became widely used and economically practical only as recently as the early 1990s. Since then, all sectors of technology have boomed into the realm of what was considered science fiction 70 ago. Will home-based 3D printing be next? As the industry begins to grow in Acadiana and around Southern Louisiana, we asked people working with 3D printers to weigh in on the benefits and future of this fascinating technology.

Local 3D Printers

Adrienne Trahan, Crowley, and James Catalano, Baton Rouge, are the owners and creative thinkers behind Future Factory, which began in New Orleans. The couple earned their bachelor degrees in Architecture from LSU and also studied at the Washington Alexandria Architecture Consortium in Washington, DC focusing on design/build projects and furniture making. Their 3D work ranges from geometric jewelry to scale models of architectural projects and monuments, like Angkor Wat.

Future Factory uses a variety of CAD software for 2D and 3D creations. James says their machine, the MakerBot 2X, uses “Fused Deposition Modeling– a process that melts small amounts of filament, which is then laid down in very small layers– measured in microns, building up until a model is formed. This is an additive process, which has no waste.”

When asked about how the pair first became interested in 3D printing, James answers: “Adrienne and I collaborated on a design competition in our senior year of Architecture school, which required a 3D printed model. We spent a few days designing an object to be printed, and sent it off to our school’s printer. Overnight our idea was transformed into a real life model of our design. We were blown away! To be holding something that only existed as digits in the computer a few hours before was so compelling, we almost immediately knew we wanted to be involved with this technology in the future. We spent months afterward researching the technology and trying to find cheaper solutions for expressing our creativity.”

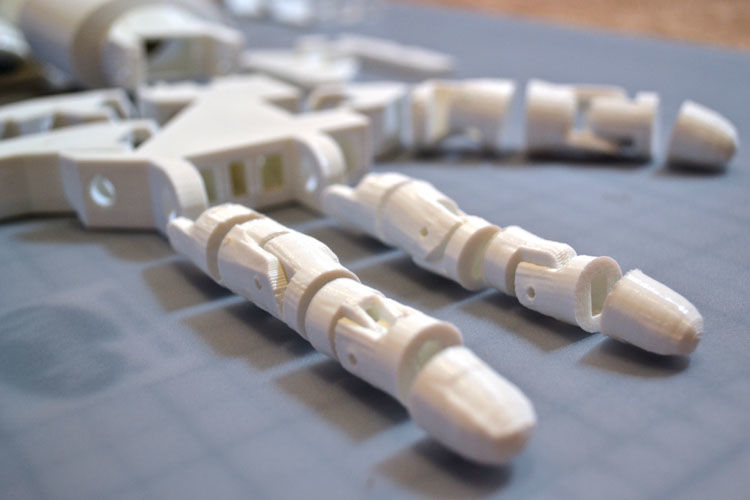

After some research, purchasing a printer, starting a business and creating a great-looking website, Future Factory was up and running in late December of 2012. What are they capable of making, we asked? “We can make anything! Well mostly anything,” says James. “Our custom production has been very unique. We have made business logos, cookie cutters, wedding toppers, jewelry, product prototypes, architectural models and we recently printed a robotic arm! Our machine can print in a variety of strong plastics, including ones that can flex, and one type that is infused with wood!”

3D Printing And Biomedicine

Future Factory is one of many companies, along with at-home 3D gurus, venturing into the world of prosthetics and biomedicine. Richard Van As of Johannesburg, South Africa, created the first Robohand after losing two fingers in an accident. Richard published the design and coding for his 3D printed fingers and hands as open source technology; Robohand has no patent, and the design is available for free. Biomedical technology is now constantly benefitting from open-sourced 3D printing. In February of 2013, the FDA approved a 3D printed skull implant that can be surgically fixed into patients’ skulls after car accidents, head trauma or bone cancer.

Printing Your Ideas

Until 3D printers become household items, Acadiana residents can turn to 3D printing professionals to print their every whim. Future Factory says: “Our clients range from distinguished professionals to high school entrepreneurs. It has been an amazing experience to see how the local people are coming up with creative ideas. We are constantly reminded that everyone has a natural tendency to be a ‘maker’ and a background in design is not necessary, only the desire to create. Most objects are small, usually no bigger than a grape fruit. 3D printing allows for a level of precision, speed and affordability never before achieved. Just about anyone can fulfill his or her desire to turn an idea into a tangible object, in a matter of hours.” Depending on the size of the object you wish to print, and the height at which you chose to layer the filaments, printing could take anywhere from a few minutes to many hours.

If reading this article has gotten you excited about printing your latest idea, take this advice on getting started. According to Future Factory, “Most of our business begins with an e-mail or a phone call. Some clients send us 3D digital models through the Internet, or we custom model their ideas based off sketches or simple conversations.”

In addition to their own website, futurefactory3d.com, James and Adrienne are both listed for hire on a website– makeXYZ.com– that allows individuals to contract out smaller printing jobs to local 3D artisans. There are six printers listed from the Acadiana area and even more from Baton Rouge and New Orleans. The website also boasts open source models for ideas, like a Google Maps ping birdhouse (a “ping” is the location dot on a Google map) and coffee cups.

Put pen to paper, think about dimensions and call or email a local printer to discuss their printing capabilities. “There is something magical about taking a 2D sketch and making a 3 dimensional object from it,” says James. You can feel that magic too as you watch your ideas become a tangible reality before your eyes in the form of plastic filament.

Idea Zoo

Lafayette-based prototype studio and digital fabricator, Idea Zoo, is another local option for 3D printing. Idea Zoo’s creator, Jacques Dugal, is a 2011 UL graduate with a degree in Industrial Design and a knack for printing. “My interest in 3D printing began while in school,” Jacques explains. “I built a self-replicating 3D printer. From there I just taught myself everything about it (3D printing); I wanted to learn everything I could.” After school, Jacques moved to New Haven, Connecticut to work for a prototype company. Two years later he returned to Louisiana, and started Idea Zoo with his friend– Josh Williams– and wife– Ashley Dugal.

Idea Zoo boasts six 3D printers capably of making, as Jacques says, “all kinds of stuff!” The company produces mostly engineering prototypes for chemical engineers. “We also do a lot of work with independent inventors and designers,” explains Jacques, “to help them develop their ideas further.” Recently, Idea Zoo forayed into the world of biomedical engineering while working with a local medical startup. Idea Zoo is also one of many 3D printing companies to print a Robohand.

Clients at Idea Zoo range from the super prepared– those likely in engineering or design who have their own 3D models already and just need them printed– to the adventurous dreamer. “Some people just have an idea,” expounds Jacques. “They come to us with whatever they have– a napkin drawing or computer sketch– and we’ll draw it out for them in a 3D format then figure out what they need for their product.” Although Jacques is on MakeXYZ.com, clients can easily find him at IdeaZooLA.com as well.

The Future of 3D Printing In Acadiana

Jacques believes that the future is bright for local customization of products in Acadiana. “3D printing opens up the world of fast customization and more localized production of products. With 3D printing, you can get something produced on a small scale for local people– products that may only be necessary for regional people like gear drives for oil companies.”

We asked James and Adrienne about their vision for 3D printing in Acadiana and around the world, and this is what they said: “3D printing will touch every part of the world in the coming years. It’s the next big wave of design tools. We think that many businesses in the Acadiana area could benefit from the speed and accuracy of 3D printing. Architecture firms to bakeries to entrepreneurs; 3D printing can help make your ideas a reality. From our experience, 3D printing is a wonderful tool, but it is one machine in a vast arsenal of tools that bring forth ideas, services and products. 3D printers will change how the world sees customization and the speed of manufacturing, but one day they will be replaced by something better. The true success behind this technology lies in the minds of creative and technically inclined people who can not only conjure ideas, but also use the proper tools to fabricate them.”